Nexter Color-System Sp. z o. o. has been operating on the market since 2004

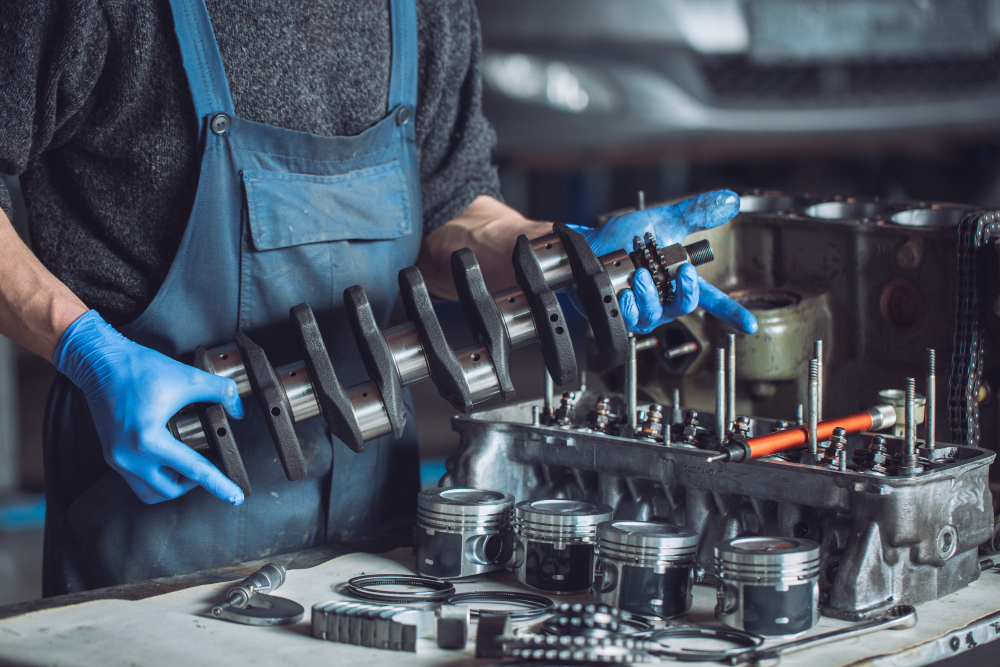

We employ qualified staff, which includes painters, mechanics, welders, tinsmiths, people operating a shot-blasting shop, employees for mountaineering work, people dealing with UDT approvals, quality controllers and others.

NEXTER COLOR SYSTEM

We operate in the field

1. Large-scale paint shop Mikołów ul. Kosciuszko 61b

2. Abrasive blasting – shot blasting (steel / aluminum / stainless steel)

3. Service of cryogenic tankers, buses, construction machines, etc.

4. Accident repairs of trucks, tankers, concrete mixers, etc.

5. Distribution of paint materials by PPG Industrial

OUR OFFER

Shot blasting with automatic shot recovery (sharp-edged steel shot / corundum) is located in the paint shop hall. Shot blasting has two working levels. The shot-blasting plant prepares the surface for painting, therefore the cleaning degree SA 2.5 is our standard. The granulation of the shot and the type of abrasive – variable – depends on current needs

Starting from 2010, we provide service on an area of 900 m2 (7 entrance gates) service of tank trucks and cryogenic tanks. The scope of our services includes repairs, modernizations, legalizations, post-accident repairs, etc. A professional team of trained and experienced employees in various fields of vehicle mechanics, led by professional management staff, ensures comfort and safety of each commissioned job.

The services we offer are made on the basis of varnish materials indicated by the customer or on the basis of varnish materials of the PPG concern, which in its offer has: lines of water-soluble acrylic varnishes (buses, trucks, tankers, etc. used in commercial transport) and a line of industrial varnishes (machines structures, silos, etc.)

Vehicle service

Service of trucks and cryogenic tankers is equipped with, among others:

01. Helium detector

02. Vacuum pumps

03. TEXA computer diagnostic equipment, WABCO system diagnostics

04. Car - MOBILE SERVICE OF CRYOGENIC INSTALLATIONS

05. A set of equipment for servicing tankers for transporting refrigerated and liquefied technical gases, class II acc. ADR

06. RENTAL OF CRYOGENIC TANKS

Dodatkowe informacje

PERSONEL

Zatrudniamy wykwalifikowany personel w skład którego wchodzą lakiernicy , mechanicy , spawacze , blacharze , osoby obsługują śrutownię , pracownicy do prac alpinistycznych, osoby zajmujące się sprawami dopuszczeń UDT , kontrolerzy jakości i inni.

Lokalizacja

Hala lakierni znajduje się przy trasie szybkiego ruchu ( nr 81) w odległości 8 km od Katowic w kierunku Mikołowa (trasa na Cieszyn), na terenie byłych zakładów autobusowych Jamna –Bus

iNNE

Dysponujemy pełną dokumentacją techniczną stosowanych materiałów lakierniczych takich jak; PZH, MSDS, PDS

PZH – Państwowy Zakład Higieny

MSDS- Materiałowa Karta Informacyjna Bezpieczeństwa

PDS – Karta Technologiczna Produktów

Paint shop hall

Paint shop hall

The paint shop is located on an area of approx. 4200 m2, we have

1- Unloading crane load capacity 5T

2- A gantry crane with a load capacity of 10 T

3- 4.5T, 7.0T and 1.5T forklifts

4- Trolleys (“goats”) for internal transport

5- Four professional painting chambers with dimensions of 14 m X 4.5 m X 4.5 m. The chambers have a temperature control range of up to 70°C. All 4 chambers are adapted to water-based varnishes.

6- Two drying chambers of 14m X 4.5m X 3m

7- Two painting chambers with dimensions of 5 m x 2.5 m x 3 m

8- One painting chamber with a dryer for painting small details in a belt system (up to 150 kg).

9- Electronic 24-hour climate control system

10-Paint application systems: SATA paint guns, WAGNER hydrodynamic pumps, WAGNER hydrodynamic pumps with electrostatics. GRACO thick mass application pump.

11-Quality control system using: induction thickness gauges, laser thermo-hygrometer, roughness gauge, gloss gauge, conductivity gauge, lattice test device, paint combs and others.

12-Warehouse space in the hall of approx. 300 m2 and a monitored parking and storage yard with an area of approx. 5,000 m2.